What is CMMS? The Complete Set of Business CMMS Knowledge You Can't Ignore

In the era of digital technology, businesses are best to apply innovative software in management, administration, supervision, and maintenance to take on the likes of their competitors.

The birth of intelligent technology software improves work efficiency and saves time and costs of management, operation, maintenance, and tracking of all assets of the enterprise. So what is CMMS? What benefits does CMMS bring to your business?

Let's dive into finding the answers in today's article.

What Is CMMS? Advantages That Businesses Shouldn't Ignore

#1. What is CMMS?

CMMS (Computerized Maintenance Management System) is a tech-based solution that optimizes the process of managing, monitoring, automating, and deploying maintenance activities for businesses. This software helps managers keep track of all devices and assets of the business.

At the same time, it centrally stores all maintenance information such as schedule maintenance, tracking maintenance history, asset parameters, management of inventory and employees, tracking maintenance tasks, etc.

Using CMMS, managers will plan and assign work more scientifically. The technician team will carry out the work quickly, safely, and effectively based on the detailed work plan.

CMMS is a cost-optimized device maintenance management software for businesses

#2. Required Features Of CMMS

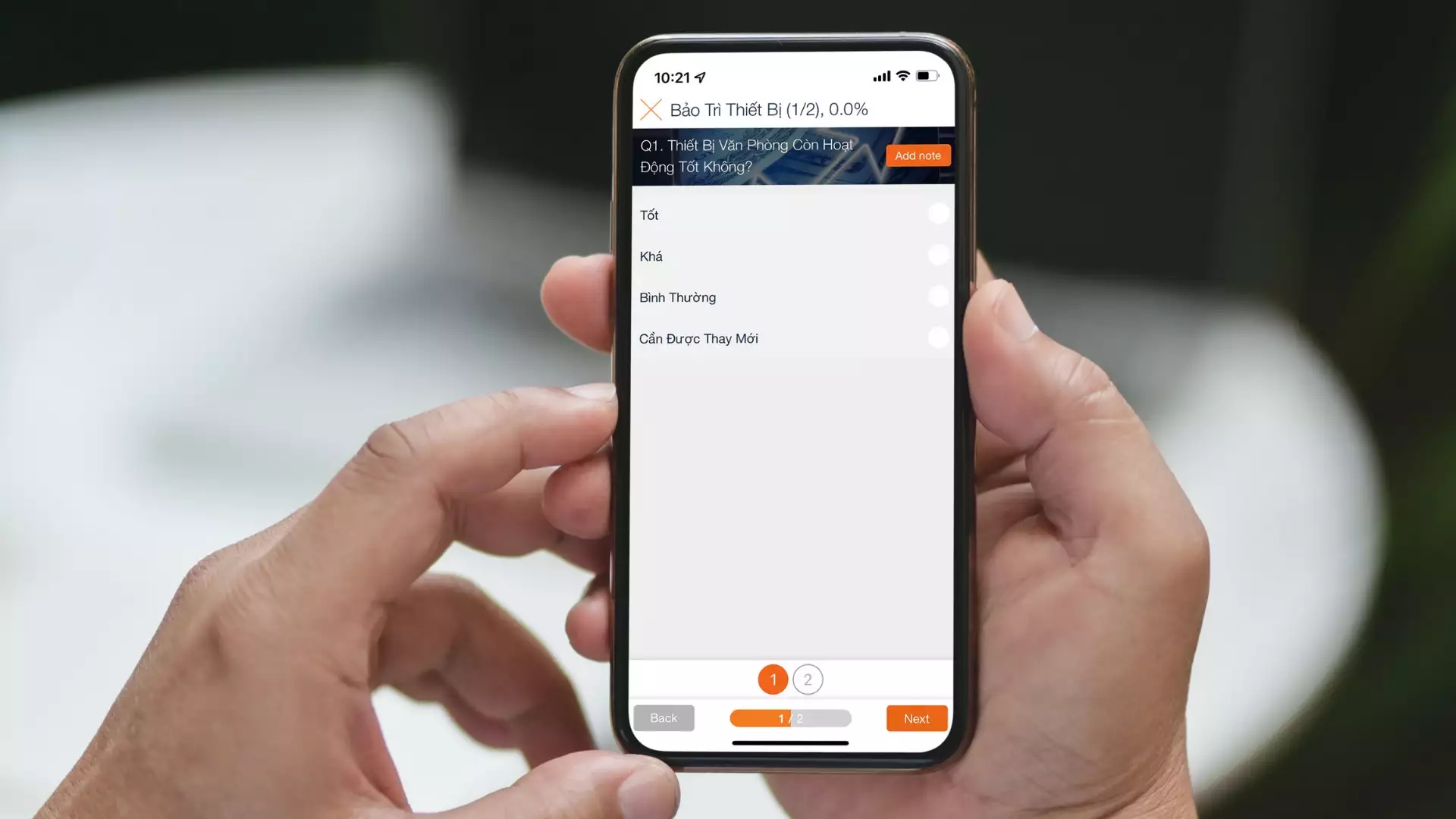

2.1. Maintenance Work TrackingWith this feature, the manager could select equipment, broken machinery, fault description, etc., to assign from technical staff to handle. Another desired feature of CMMS is to track maintenance work with CMMS software to help technicians complete and report work quickly.

After the repair is completed, the maintenance staff only needs to mark the work "completed", and the manager will receive immediate notification.

2.2. Plan MaintenanceWhen planning begins, the maintenance team needs a reliable maintenance schedule. CMMS software automatically suggests periodic scheduling work. Simultaneously, it sends reminder notifications to each employee.

Scientific maintenance plans help businesses minimize work overload and ensure no errors in any task.

2.3. Control And Require Maintenance Personnel

It is regular that maintenance staff regularly receive work requests of equipment maintenance from the management and other departments and divisions. Particularly, when there is a device broken, they might be informed about this incident to handle it promptly.

The question is, how can they be informed early? Traditionally, people often use email or message apps to report incidents. These methods would work in a particular way. That said, it is difficult to follow up the incidents. You could find it complicated to view the incident report later.

It could also be a problem when a customer encounters a technical error while using the product. Equipment maintenance management software CMMS is a tool to receive, process, and monitor the status of such requests.

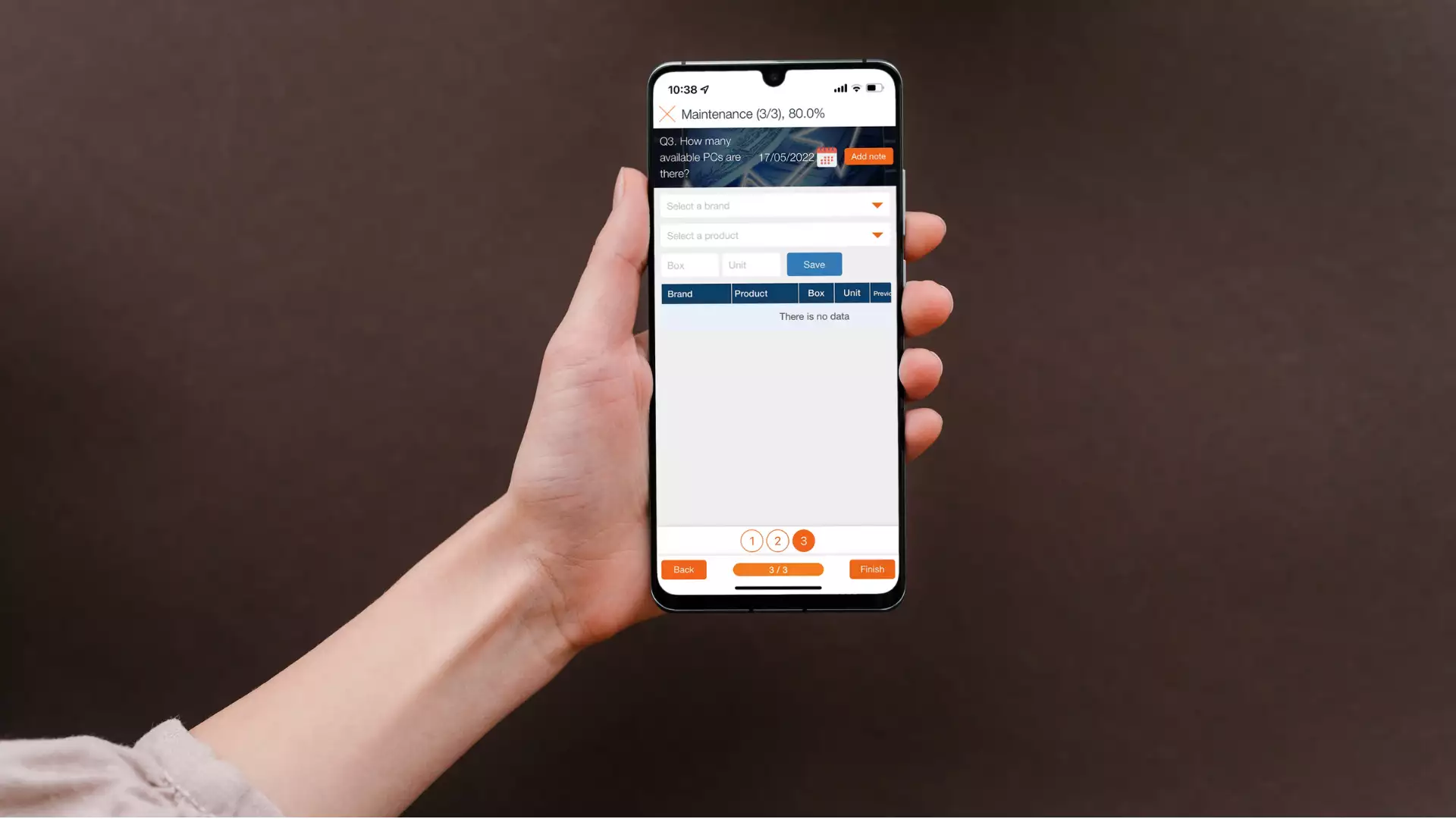

Control and request maintenance personnel via mobile phone

2.4. Save Maintenance HistoryMany maintenance teams sometimes have to deal with many outdated assets. This property group has a strong history of repair and maintenance. Therefore, when an incident occurs, you must know the situation and how to handle the previous times.

After the equipment is repaired, all information will be saved in the machine's maintenance history. The maintenance staff can review it many times before troubleshooting the next time.

2.5. Inspection And CertificationMany CMMS systems keep a history of each equipment maintenance action. The information stored has gone through the verification process and cannot be changed.

Therefore, equipment maintenance history is extremely useful in the event of an accident or insurance claim. Inspectors can rely on maintenance history to verify if the job has been completed.

According to the ISO certificate, CMMS equipment maintenance management software will save all data on the system, so it is easy and convenient to standardize.

#3. The Advantages Of CMMS

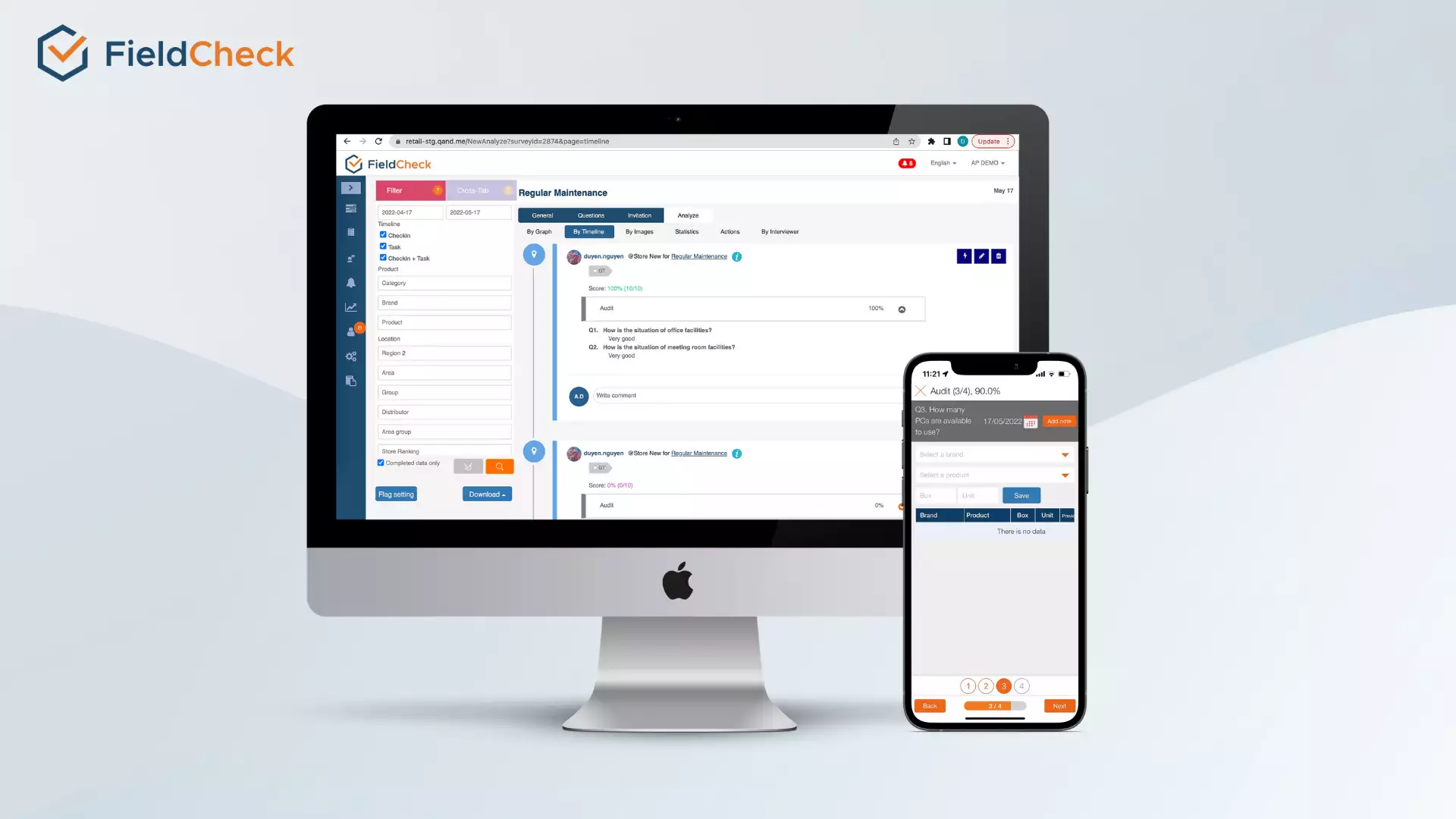

How does FieldCheck help with the CMMS solution? Let's find out in the main content below.

3.1. Reduced Overall Maintenance CostsMany businesses utilize CMMS to optimize equipment maintenance costs effectively. The solution with integrated intelligent features helps improve the productivity of technicians, especially for those who have to handle a host of tasks in a tight schedule.

Additionally, CMMS assists businesses in the following tasks:

- Reduce the number of breakdowns, and prolong the life of machinery and equipment.

- Reduce labor and technical staff costs by cutting OT hours and increasing work productivity.

Unexpected machine breakdown appears to be a nightmare for the maintenance manager. These incidents caused the production system of the enterprise to be shut down. Increased machine and personnel downtime lead to severe losses.

Managers estimate that the downtime cost of a business after each machine failure is about $100,000 an hour. This seriously affects the business's sales, product quality, and reputation.

To fix problems, businesses need to have a proactive maintenance plan and consistent and scientific integration with CMMS equipment maintenance and management software.

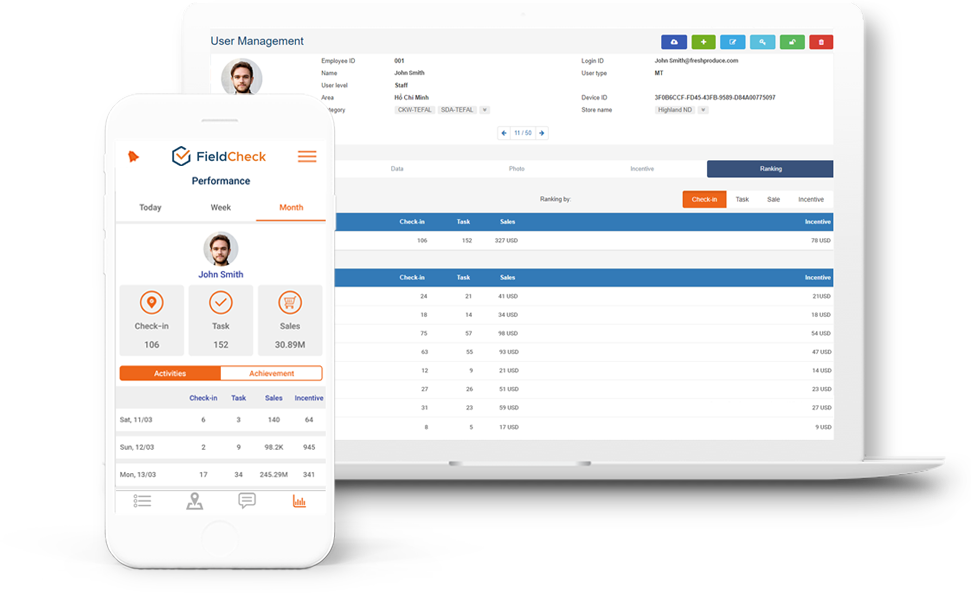

3.3. Increase Work ProductivityIn addition to shortening the downtime, CMMS also increases the working efficiency of enterprises. Software application when checking, monitoring maintenance activities, maintenance KPIs, and working progress of staff on the electronic system.

This helps managers easily control and diagnose machine problems as they could detect and promptly solve problems that may occur during equipment operation.

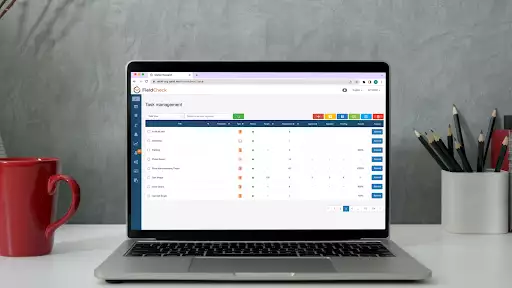

3.4. Stock AuditFieldCheck's CMMS maintenance management software makes managing and controlling inventory, spare parts, etc., easier and more efficient. This application helps the technical team know what tools, equipment, and spare parts are in stock and use them appropriately.

This shortens troubleshooting time while reducing downtime of machinery and equipment. Thereby, you could minimize costs incurred in the period of the business.

This solution also helps businesses keep track of inventory details, tools, and spare parts... in a difficult way. Thanks to that, the machine repair and preventive maintenance plan during the business period went smoothly.

Simple, clear, detailed inventory control

3.5. Track Your Assets and Important DataCMMS helps managers easily track assets and important data. Detailed asset and document tracking features include:

- Monitor the exact order of jobs

- Keep track of maintenance history

- Prepare purchase and sale invoices for assets and equipment

- Reporting and analyzing product maintenance results

- Manage inventory and assets of the business

- Collect, and analyze asset health and intelligent maintenance

- Report and define maintenance KPIs and distribute work to employees

This helps businesses control assets, machine health, and specific maintenance information to make more accurate business decisions.

3.6. Ensuring Safety For WorkersWith the CMMS application, workers' health and safety will be guaranteed as the software provides businesses with many smart features such as:

- Basic safety requirements

- Keep track of employee health check logs

- Monitor machine safety

- Help employees easily grasp information and equipment maintenance plans

The application of CMMS software in equipment management and maintenance helps employees be more responsible. Managers also easily know if the maintenance engineer is doing the right job on time or not.

The reason is that after the employee completes the work, the manager will receive a notification on the system. This helps ensure employees are not idle.

At the same time, limited employees are busy with a mountain of work simultaneously. When work is regularly replenished, unnecessary overtime will be reduced.

Control employee work and reduce overtime

Which Businesses Should Use CMMS Software

Any business needs CMMS maintenance management software that helps businesses plan and manage maintenance activities more effectively. Here are some subjects that should use FieldCheck's CMMS software.

#1. Manufacturing Industry

The manufacturing industry, especially companies that own many lines, machines, forklifts, heavy equipment, etc., require regular maintenance.

The application of CMMS will bring many benefits in managing operating activities, maintenance and replacement, as well as technical personnel costs.

#2. Internal Transportation Facility

Building transportation facilities include building management companies, apartment buildings, cinemas, and government buildings, etc. Every piece of equipment in buildings requires regular maintenance to ensure safe operation.

CMMS equipment maintenance management software will help you structurally solve HVAC, water supply, elevator, and equipment problems.

#3. Transport Company

That transport companies have to manage a bunch of vehicles and means of transport especially needs maintenance services to ensure the quality and the normal operation.

FieldCheck integrates features like CMMS software, helping you create tasks to check equipment health at work. Through it, you could know the status of the machine. If anything happens, you could immediately report it to the stakeholders to seek the suitable actions promptly.

You will no longer have to worry about machinery stalling or damage when you need to perform some important work. Above is the information that shows what CMMS is and the features and benefits that the application brings to businesses.

We hope today's article is helpful to you. If you want to experience the product or need to try the service, don't hesitate to get in touch with us to schedule an appointment soon.